Bafgh Steel

The rebars produced in Bafgh Steel are always manufactured and distributed according to the standards desired by the customers. Due to the high demand for high-quality structural rebars, particularly A3 and A4 grades, in the domestic market, we consistently offer our customers a wide range of products. Thanks to our methodical planning and adherence to consumption patterns, we are always capable of promptly supplying the items requested by customers.

Utilizing a rebar rolling line equipped with advanced production technology from Bascotecnia of Spain, a preheated furnace incorporating German technology, Lagun Artea production line automation from Spain, Italian OMV automatic packaging, cooling equipment manufactured in Sweden, and other equipment sourced from reputable manufacturers, predominantly European, has enabled Bafgh Steel to produce highest-quality rebars.

Packaging of Bafgh Steel Rebars

Rebars produced at Bafgh Steel are typically packaged in 2-ton bundles, each with a length of 12 meters and minimal weight tolerance. Each bundle of rebars is secured with four binding wires. This not only ensures security during transportation and minimizes the volume of the bundle, but also reduces the risk of straps becoming loose and decreases the weight of the bundles. As a result, buyers will be completely satisfied with the flawless and secure delivery of rebar bundles. This type of packaging also facilitates handling by magnet cranes and does not pose challenges for cranes equipped with hooks.

Quality Control and Examination of Products

The quality control process for Bafgh Steel rebars begins with the delivery of ingots, before they enter the rolling process. In addition to examining the appearance of the ingots, our specialists compare the quality certificates of each ingot with its specifications. During production, our specialists in the quality control department supervise all steps. The thickness and apparent shape of rebars are examined on the spot, and if they do not match the specifications, corrective actions are immediately implemented in the production process. Rebars are inspected for length before packaging to ensure they adhere closely to the ordered length with minimal deviation. By employing statistical quality control methods in accordance with Iran National Standard, rebars are sampled during the production process.

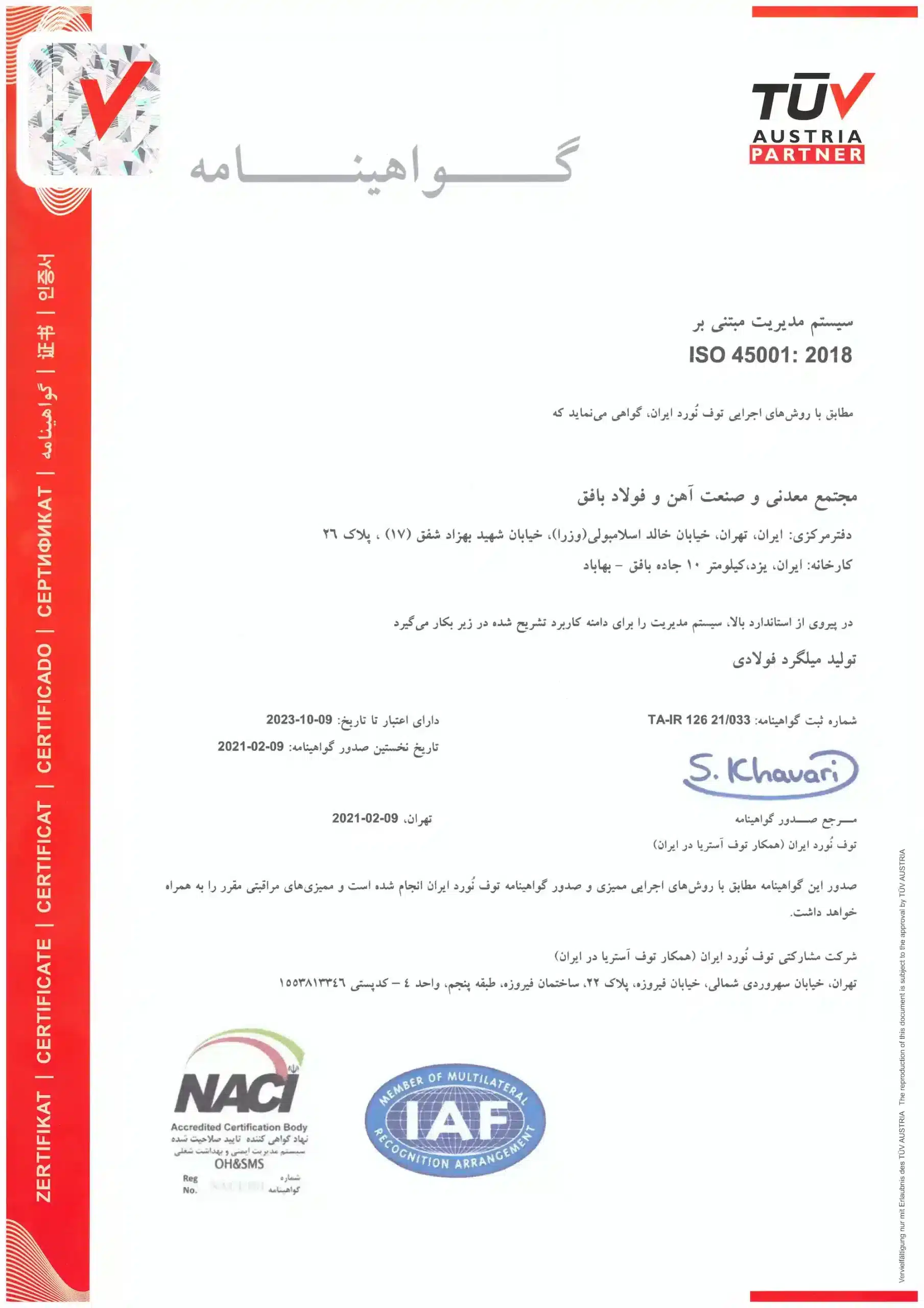

These samples undergo various tests including tension, bending, re-bending, fatigue, hardness, and more. Holding the ISO17025 certificate (reference laboratory accreditation certificate) from the Institute of Standards and Industrial Research of Iran (ISIRI), reports provided by the Bafgh Steel quality control unit are deemed credible for various projects across the country.

Features of Bafgh Steel Rebars

Bafgh Steel rebars possess different features depending on their production grade. The table below outlines the physical and mechanical characteristics of structural rebars.