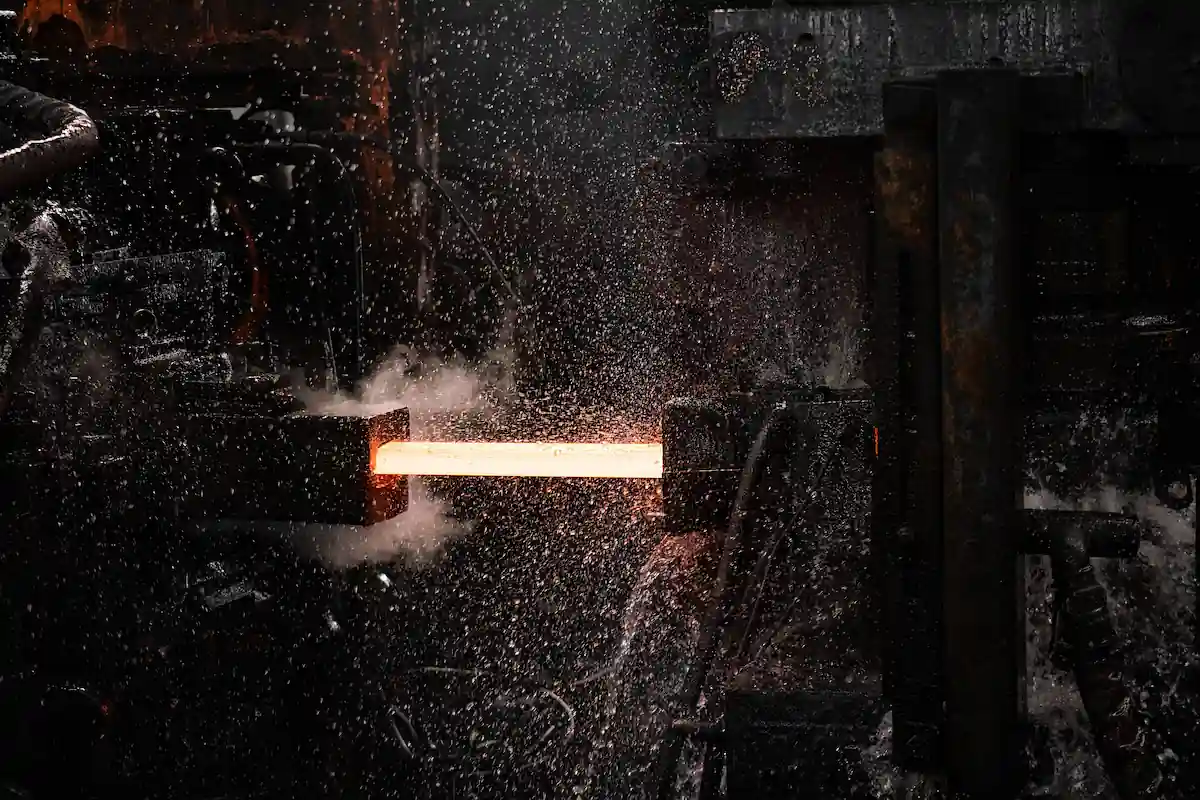

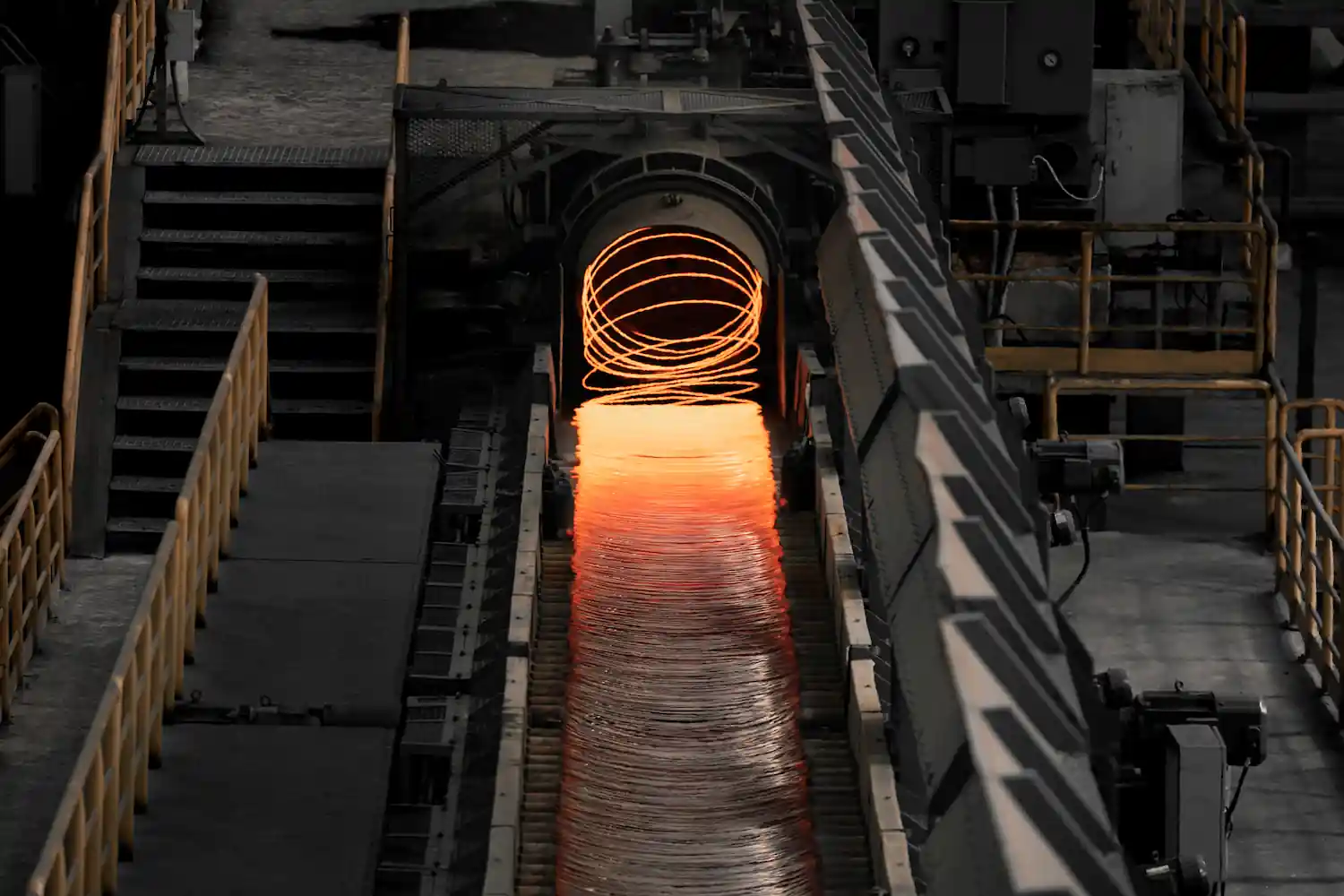

Rebar and Wire Rod Production Line

Yaran Industrial Group took its first visionary step by inaugurating a rebar and wire rod production line with a capacity of 550 thousand tons per year. Being in the vicinity of iron ore mines in central Iran and Choghart, the resource-rich desert has proven to be a fertile ground for establishing the production line, the products of which are being utilized in many domestic and international projects.

The widest range of products; a step towards the facilitation of construction projects

With years of industry experience, advanced equipment, and our skilled staff, we offer an extensive range of rebars, catering to a variety of construction needs:

- Rebars produced according to both Iranian national standards and German DIN standards for export purposes

- Production in sizes ranging from 8 to 40, with custom length options

The successful implementation of the industrial rolling line for rebars marked the beginning of our efforts to excel in this industry as the Bafgh family. In our journey, we have established a significant presence in the Iranian steel industry with our team of 300 skilled professionals in various fields of expertise. But what has made us the best?

- Possessing a production capacity of 550 thousand tons of rebars per year

- Utilization of cutting-edge technologies in quality control laboratories

- Ensuring quality control at every stage, aiming to eliminate potential deficiencies and conforming with national standard No. 3132, titled “Hot-rolled steel bars for reinforcement of concrete-specification and test methods”

- Operating a preheating furnace with a capacity of 100 tons per hour

Actively involved in Iran’s industrial sector; dedicated to preserving the country’s natural environment

- In addition to prioritizing the production of top-quality steel rebar that caters to the demands of both small and large projects without compromising quality, we are equally devoted to environmental conservation. In active support of our commitment, we have undertaken the following measures:

- Implementing water treatment and recycling protocols within our production processes

- Systematic disposal of effluent and sludge generated during the water treatment process, utilizing the treated water for the irrigation of the factory’s manually planted green area

- Effectively managing energy consumption, optimizing furnace insulation, and consequently abstaining from using Mazut during winter

- Engaging in desert greening initiatives and annually planting saplings in the outskirts of the city of Bafgh

Remaining as top producers of high-quality products; always our plan here at Bafgh Steel Co.

- We believe that achieving recognition and expertise in the field of rebar production and also earning the favor of customers is not a matter of chance. The interest and preference for a steel product are derived from years of scrutiny and analysis of the results obtained from quality control laboratories along this journey. In producing standard rebars for projects where prioritizing standards and quality are paramount, we have conscientiously considered both qualitative and quantitative aspects. For instance:

- Using high-quality ingots with standardized and proper chemical and mechanical properties

- Employing cutting-edge machinery, including tensile strength, compressive strength, and bend and re-bend machines

- Closely monitoring each production step and conducting mechanical tests on factors such as tension, bending, and re-bending.

Hence, to contribute to the enrichment of Iran’s industry, we consistently rank among the top producers.

Gallery