Produced through MIDREX® Method

The iron ore pellets required by the factory are supplied from neighboring pelletizing facilities. Due to the abundant nearby mineral resources, these pellets enjoy highly favorable purity and chemical properties. In the direct reduction process, in the presence of hot reducing gases, these pellets undergo a reduction reaction, losing some of the oxygen they contain and transforming into sponge iron.

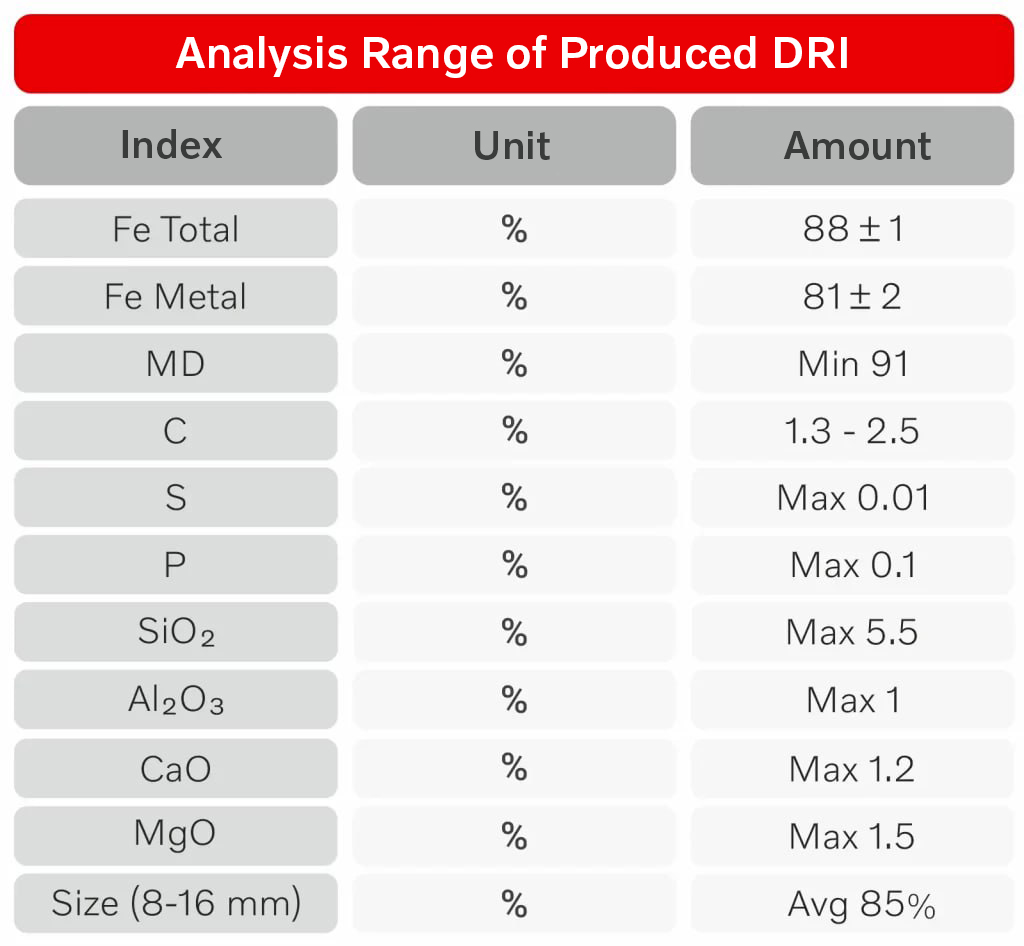

Quality Control

Bafgh Steel [Sponge Iron] Chemical Analysis

The low phosphorus content and the appropriate iron percentage in the alloy steel sponge make this product suitable for use in both induction and electric arc furnaces.

In the table below, you can find the analysis of Bafgh Steel sponge iron.