Earthquakes, an enduring scar on our nation, Iran. Echoing the names of many cities in our country. From Manjil and Rudbar to Bam, and from Sarpol-e Zahab to Khoy, our fellow countrymen have been victims of severe earthquakes, and the post-earthquake damages have brought bitterness into their lives.

A natural disaster whose prediction is not practically possible; however, the experiences of earthquake-prone countries such as Japan have shown that reducing casualties through the construction of buildings resistant to this powerful force is achievable.

In accordance with that, in this day and age, many reputable professionals and companies prioritize the utilization of the newest technology and high-quality rebars to strengthen their construction projects.

What Is A4 Rebar?

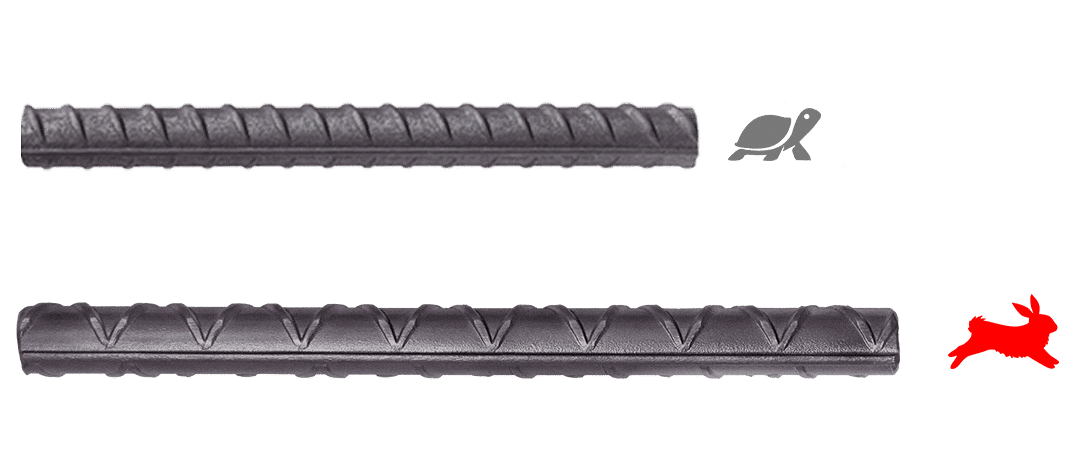

A4 rebar, also known as S500 according to the Iran National Standard, is a type of structural rebar known for its exceptional strength compared to other types of reinforcement bars. In fact, this type of rebar can withstand a minimum of 500 Newtons per square millimeter before yielding. Due to its strength and cost-effectiveness, there has been a growing utilization of this rebar in construction projects.

Optimal Strength

Cost-Efficient

Cost of A3 Rebars – (Cost of A3 Rebars × 80%)

Swift and Precise

Premium Compactness

Another advantage of reducing the number of rebars used, due to the higher tensile strength of A4 rebars compared to A3, is the reduction in structural design space, or in technical terms, a decrease in column dimensions, and consequently, an increase in the usable space of the structure.